Turning Machines

Lathes used for turning parts were the world’s first machine tools. These machines move a static cutting tool down the length of a rotating workpiece to cut the workpiece to shape. Modern CNC turning centers use servo drives to control tool motion compared to hand wheels on manual lathes. Tools install on gang plates or turrets, depending on the type of lathe. Today’s turning centers often can perform milling and cross-drilling operations thanks to live tool spindles that are installed in turret stations that sometimes provide Y-axis movement across the workpiece center line. Turning centers are available in horizontal and vertical main spindle orientations.

Latest Products

Murata Machinery Turning Machine Features Twin Spindles

PMTS 2025: The MT1065EX twin-spindle CNC turning machine enables intricate operations such as pinch turning and simultaneous first- and second-operation machining.

Read MoreTsugami Lathe Enables High-Accuracy, Multifunction Machining

PMTS 2025: The SS20MH-III-5AX multifunction sliding headstock lathe can make complex-shaped workpieces with 3D curved surfaces utilizing the five-axis simultaneous control and Capto C3, 30-position tool magazine, all from bar stock or blanks.

Read MoreFryer Turning Machine Features Large Swing in a Small Footprint

The VT Series of large-swing vertical turret lathes can be configured for turning, milling, boring and grinding in a single machine.

Read MoreHurco Slant-Bed Lathe Features Live Tooling Capabilities

Hurco’s TM8MYi slant-bed lathe comes equipped with a Renishaw swing-down tool setter and a bi-directional, servo-driven live tool.

Read MoreOkuma Lathe Features Rigid Construction for High-Accuracy Machining

Okuma America Corp. features the LB2000 EX III horizontal lathe, equipped with the OSP-P500 open-architecture control designed exclusively for Okuma machines.

Read MoreExpand Machinery Mill-Turn Enables Flexible Turning Performance

IMTS 2024: The Gen Turn CW 42MY is a small footprint eight-axis mill-turn lathe with a full-sized counter spindle.

Read MoreFeatured Posts

OEM Moves From Automation Implementation to Refinement

Automating challenging parts for full-weekend automation requires substantial process refinements that can significantly boost throughput.

Read MoreUpgrading Bar Feeder Components with Metal 3D Printing

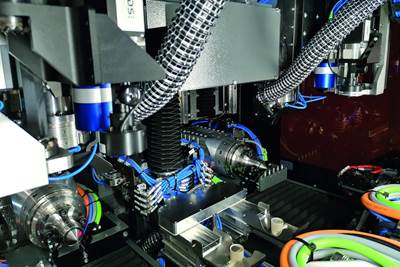

Index is exploring redesigning and optimizing parts for bar feeders inside its multi-spindle turning centers using a low-cost metal 3D printing platform from One Click Metal.

WatchA Contract CNC Shop in Transition

Denver Precision Products is in a transitional mode in two respects: company leadership and adoption of new multifunction machining technology and processes.

Read MorePrecision Machining Technology Review: November 2024

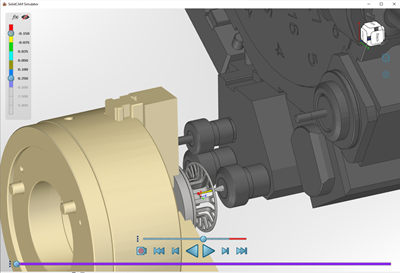

Production Machining’s November 2024 technology showcase includes some of the latest technology from Vericut, Hurco, the L.S. Starrett Co., LNS North America, Fryer Machine Systems and MachineMetrics.

Read MoreGrowth Comes When Machining Challenges Are Met

Manufacturers such as SDP/SI that embrace machining challenges ultimately find ways to become more efficient and profitable operations.

Read MoreAn Automated Answer for Machining Ball Pins

This new vertical turning center with measurement and robotic automation processes is able to produce vehicle ball joint ball pins in 7 seconds.

Read More

.jpg;maxWidth=300;quality=90)