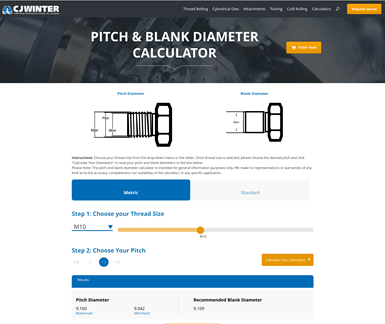

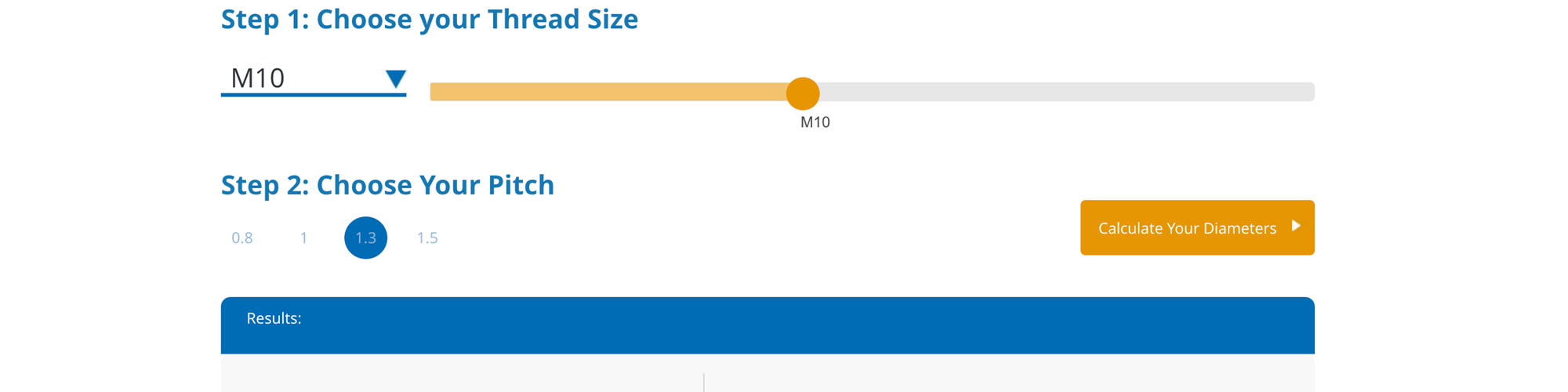

Users select the thread size and desired pitch to generate diameter and pitch values. (Photo credits: CJWinter)

When it comes to thread rolling, having the right tools can significantly streamline the process, ensuring accuracy and minimizing downtime.

Unlike subtractive processes, thread rolling does not remove material but instead moves and molds ductile metals quickly and precisely into the thread form using a cold-forming process. Thread rolling is completed using a thread rolling attachment on a multi-spindle, Swiss-type or CNC lathe. During the process, the tooth form of the thread rolls protrudes into the outside diameter of a cylindrical blank workpiece to reform the surface. The extreme pressure from the thread rolls causes the blank material to flow outward into the cavity between the thread rolls. This produces thread geometry that mirrors that of the rolls.

CJWinter, a provider of thread rolling solutions, simplifies complex calculations for engineers and manufacturers with an array of thread rolling calculators. These calculators, which are available on the company’s website, are designed to optimize thread rolling operations. Here are four:

Pitch and Blank Diameter Calculator. Determining the pitch and blank diameter is crucial for achieving precise thread dimensions. By selecting the thread size and desired pitch, CJWinter’s Pitch and Blank Diameter Calculator instantly generates the required blank diameter, along with the minimum and maximum pitch diameter values. This saves users valuable time and ensures accuracy in setup specifications, enabling smoother attachment installation and operation.

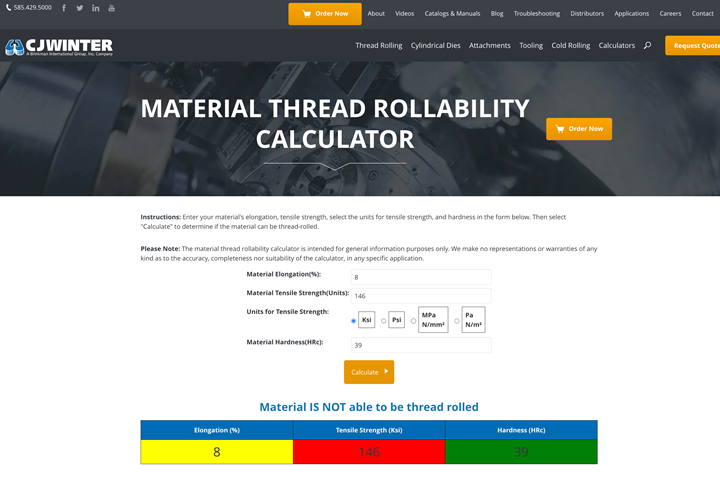

This calculator indicates whether the material is suitable for thread rolling.

Material Thread Rollability Calculator. Choosing the right material for thread rolling can be challenging. The company’s Material Thread Rollability Calculator simplifies this decision-making process by evaluating material properties such as elongation, tensile strength and hardness. With a simple input of these parameters, the calculator indicates whether the material is suitable for thread rolling. The color-coded results provide a quick visual assessment, enabling manufacturers to make informed material selections for optimal thread rolling performance.

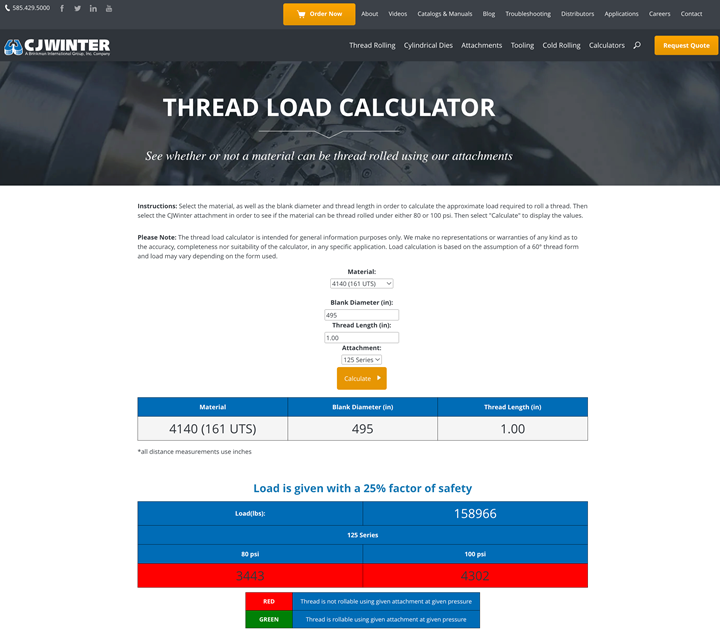

By providing load values at different rolling pressures, manufacturers can adjust parameters accordingly to achieve desired thread characteristics.

Thread Load Calculator. Understanding the load requirements for thread rolling is essential to preventing equipment damage and ensuring consistent thread quality. CJWinter’s Thread Load Calculator facilitates this by calculating the approximate load required based on material, blank diameter, thread length and the company’s attachment specifications. By providing load values at different rolling pressures, manufacturers can adjust parameters accordingly to achieve desired thread characteristics. The calculator’s interface and visual indicators are designed to simplify the process and enhance user experience.

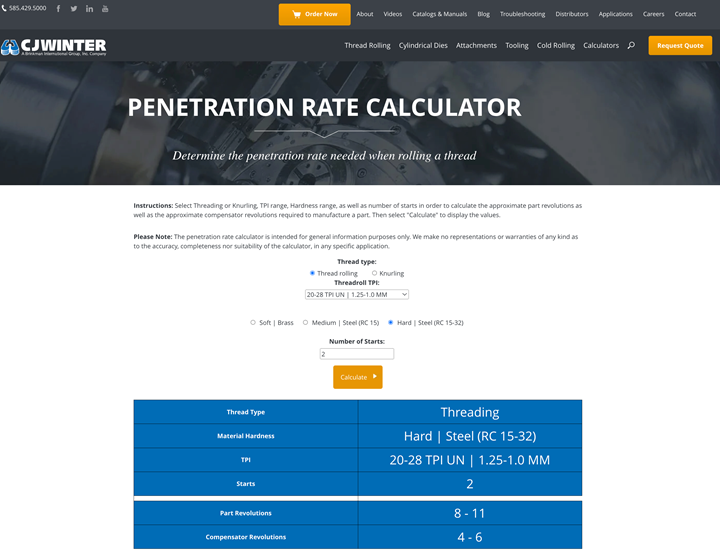

This calculator considers factors such as thread per inch (TPI), material hardness and number of starts.

Penetration Rate Calculator. Achieving the right penetration rate is vital for thread forming and knurling operations. The company’s Penetration Rate Calculator streamlines this calculation by considering factors such as thread per inch (TPI), material hardness and number of starts. By inputting these parameters, the calculator computes recommended part revolutions and corresponding compensator revolutions, optimizing production efficiency while maintaining quality standards. This tool enables manufacturers to fine-tune their processes for optimal performance and productivity.

By providing accurate calculations and intuitive interfaces, these calculators simplify complex tasks, reduce errors and enhance overall efficiency. As CJWinter continues to expand its knowledge database, users can expect ongoing advancements and improvements with the manufacturing processes.

Related Content

Producing Micro Screws for the Watch Industry

Cutting tools play a key role in machining tiny screws on Swiss-type lathes for this Switzerland-based watch manufacturer.

Read MoreRepeatability and Rigidity Are Key for Quick-Change Swiss Tooling

A rotary wedge clamping system is said to enable this two-piece, modular tooling system for Swiss-types to offer the performance of a solid tool.

Read MoreReplaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreShop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

Read MoreRead Next

Approach PMTS 2025 With a ‘Process’ Mindset

High-volume machining operations are more apt to think about the entire process of producing parts beyond the machine tools themselves. All such technology is presented at the 2025 edition of the Precision Machining Technology Show.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreThe Lost Art of Mastery

There is value to honing and mastering a craft. But it takes time and experience.

Read More

_Network-Zone_TAP-300x250-Final.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)