Edge Technologies Bar Feeder Maximizes RPM Potential

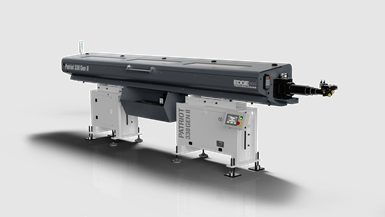

The second-generation Patriot 338 and 551 were designed for faster changeovers, ease of use and safe operation.

Edge Technologies’ second-generation Patriot 338 and 551 include enhanced features, new sheet metal and a new color scheme.

Faster changeovers, ease of use and safety were the driving forces incorporated from customer feedback and thousands of installations, the company says. Edge Technologies has equipped the latest Patriot bar feeder with quick-change guide channel sets, a larger viewing window and an internal LED light bar around the gripper area — features that ease setup and production monitoring. The main bushing device and second movable anti-vibration device (MAVD) are improved to stabilize bar stock between guide channel and lathe spindle, maximizing RPM potential.

The bar feeder also boasts major upgrades to the motion control system and human-machine interface (HMI). The touchscreen control is said to be interactive and easy to program. Programming is powerful and flexible enough to accommodate basic part processing on fixed and sliding headstock lathes as well as more advanced applications. The new Schneider motion control system is the latest in programmable logic controller (PLC) technology with built-in ethernet ports to accommodate advanced interfacing and the ability to push and pull data from a CNC lathe. The machines feature part program storage of 500 jobs.

Related Content

-

Independent Turning Cell Enables High Concentricity Precision

PMTS 2023: The RV 10 Flexmaster rotary transfer machine’s precision turning cell (PTC) is integrated in the machine as a disconnected turning cell and is free of the drive and machining factors that affect the other stations.

-

Precision Machining Technology Review: August 2024

Production Machining’s August 2024 technology showcase includes some of the latest technology from SW North America, Tsugami, Siemens, Select Manufacturing Technologies, Hurco and ECI Software Solutions — all on display at IMTS 2024.

-

Moen’s Flowing Success with Rotary Transfer Technology

The popular faucet manufacturer has adopted new CNC rotary transfer equipment to produce valves for its new generation of Widespread faucets.

.jpg;maxWidth=300;quality=90)