Motion Meeting Expedition 2023

Thun, Switzerland, was buzzing with excitement on Friday, Feb. 10, 2023, as members of the press from across the world traveled to the headquarters of Fritz Studer AG, member company of United Grinding. I was fortunate enough to attend representing Production Machining. That morning, our diverse group of journalists gathered to learn about the latest grinding equipment offerings at the international OEM’s press conference and event in the Swiss Alps titled Motion Meeting Expedition 2023.

Several company executives kicked off the annual event by presenting about the state of the business prior to revealing the company’s newest innovations, most of which include automation. After the presentations, we were led to a different building on the campus where the OEM’s new machines were displayed. Automation appeared to be the theme of the new equipment shown to us.

“There are still a lot of prejudices about automation in grinding," says Daniel Schafroth, systems division manager at Studer. There are frequently concerns that people or jobs could become redundant. “However, the opposite holds true: Automation should enable the human operators to do their work more easily, efficiently, and safely," he says.

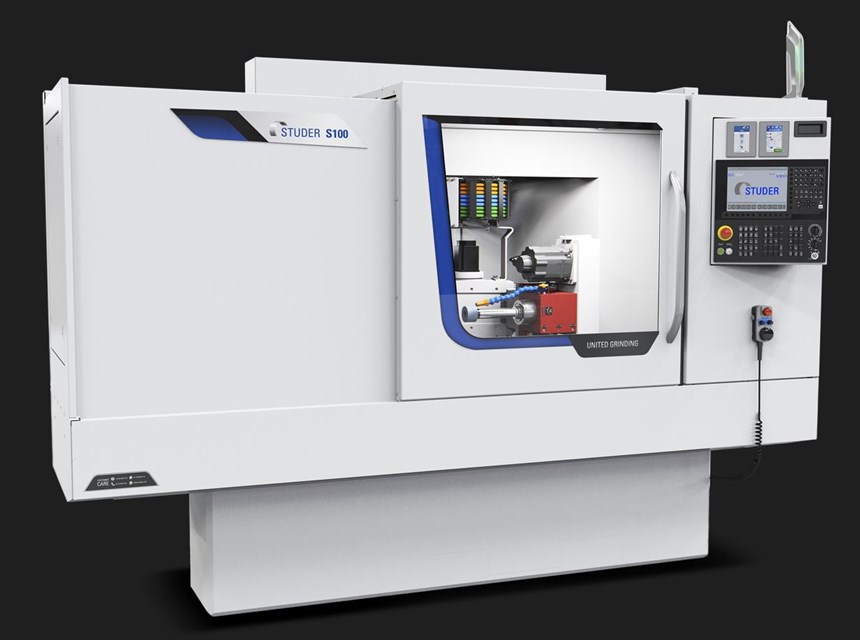

The new Studer S100 internal cylindrical grinding machine was introduced, which is the entry-level system designed for simplicity and efficiency, and is said to make operation and maintenance easier for the operator. The machine can be equipped with up to two internal grinding spindles or one internal and one external spindle. In addition to a fixed wheelhead, it can be equipped with a manual with a 2.5-degree hirth and, in its optimum configuration, with an automatic wheelhead with 1-degree hirth. On request, the machine can be equipped with a loading interface and an automatic sliding door, enabling automatic operation and high-volume production.

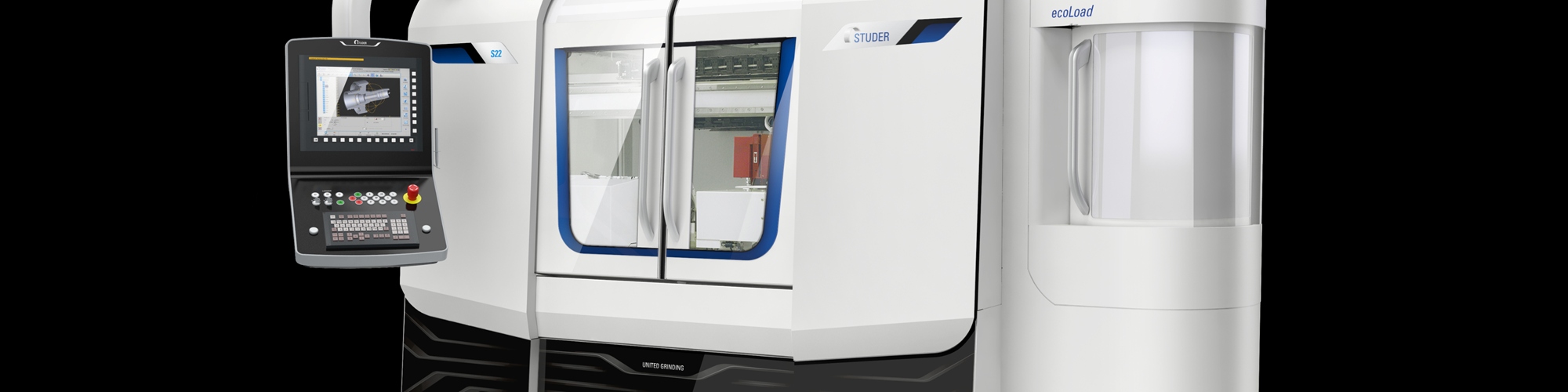

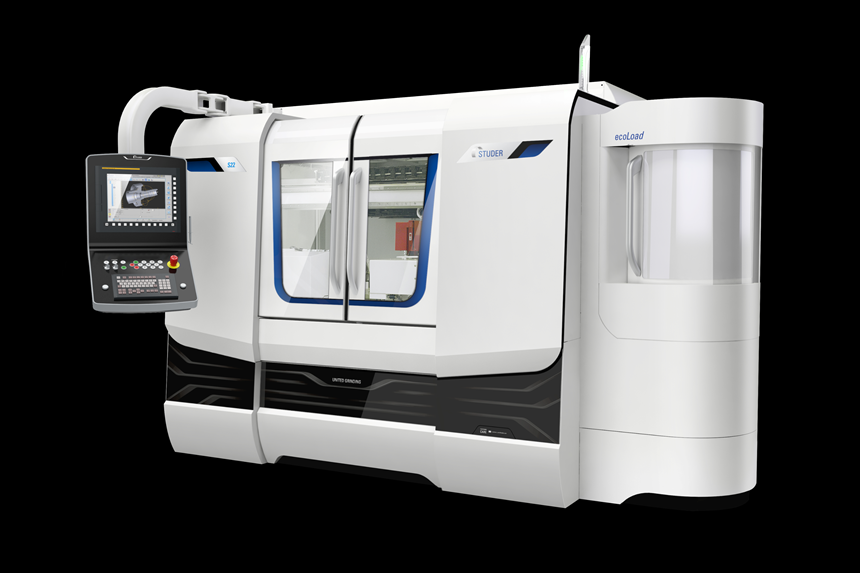

Several new loading equipment options were also presented, including easyLoad for external and universal cylindrical grinding machines on Studer cylindrical grinders models S31, S33, S22, and S41. The loading process is suitable for use as a gantry loading system for shaft parts with a workpiece length of up to 300 mm (11.8”), a diameter of up to 30 mm (1.18”), and interfering contour diameters of 50 mm (1.97”) maximum. The adjustable synchronized conveyor enables autonomous processing of 50 workpieces, maximum.

The ecoLoad for high-volume production is a cost-efficient and compact automated loader. It can load workpieces with a diameter of up to 50 mm (1.97”) and a length of 250 mm (9.85”). This is either done using a carousel magazine or an insertion prism, which can also be used as the interface for standalone tool magazines. The programming is integrated into the grinding machine control systems, which ensures short retooling times.

The uniLoad automatic loading system makes it possible for operators of the Studer S31 and S33 external cylindrical grinding machines to significantly increase productivity without any loss of quality. It is suitable for workpieces with a length of up to 350 mm (13.8”) and 100 mm (3.94”) diameter and thus covers a range of parts normally produced on these machines.

For automation when space is tight on the shop floor, smartLoad is a loading option for the company’s S11 production cylindrical grinding machine for small workpieces. With a footprint of only 1.8 square meters (19.4 sq. ft), the unit is compact and can feed in workpieces from outside the machine, using either a conveyor or a swiveling unit.

Related Content

The Advantages of Turning and Grinding on One Machine Platform

Instead of using a dedicated grinding machine or an outside grinding vendor to achieve very high surface finishes, a machine that can hard turn and grind can reduce WIP and speed part completion while taking up minimal floor space.

Read MorePrecision Machining Technology Review: February 2025

Production Machining’s February 2025 technology showcase includes some of the latest technology from Marubeni Citizren-Cincom, Murata Machinery USA, Mazak, Star CNC, Grob Systems and Schütte.

Read MoreCarbon Fiber Spindles Aim to Eliminate Grinding Variance

These spindles available on Tschudin CNC centerless grinders are designed to minimize the heat transfer factor while optimizing dimensional stability and material removal rate.

Read MoreJunker Grinding Machines Feature Modular Design

The Platform 3 series of modular grinding machines is designed to provide increased flexibility and cost-effectiveness.

Read MoreRead Next

Approach PMTS 2025 With a ‘Process’ Mindset

High-volume machining operations are more apt to think about the entire process of producing parts beyond the machine tools themselves. All such technology is presented at the 2025 edition of the Precision Machining Technology Show.

Read MoreThe Lost Art of Mastery

There is value to honing and mastering a craft. But it takes time and experience.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)